Testing-mgsecure: Difference between revisions

mNo edit summary |

|||

| Line 7: | Line 7: | ||

<br> | <br> | ||

== Disassembly instructions edit == | == Disassembly instructions edit == | ||

| Line 143: | Line 27: | ||

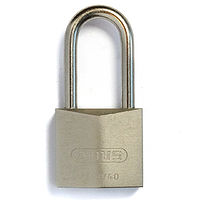

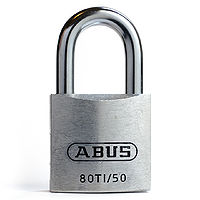

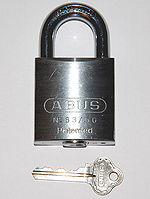

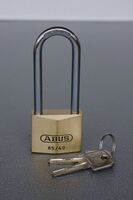

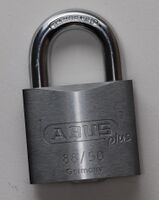

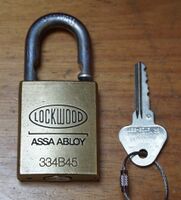

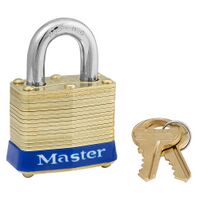

== ALL lock photos == | == ALL lock photos == | ||

<gallery widths= | <gallery widths=200px heights=200px align="center"> | ||

File:Abloy Classic cylinder.jpg | [[Abloy Classic]] | File:Abloy Classic cylinder.jpg | [[Abloy Classic]] | ||

File:Abloy Disklock cylinder.jpg | [[Abloy Disklock]] | File:Abloy Disklock cylinder.jpg | [[Abloy Disklock]] | ||

Revision as of 21:05, 30 January 2023

This page being used for testing and development

Disassembly instructions edit

Original: To disassemble a double euro cylinder, use of a pinning shoe is the preferred method. Other possibility is to use a segmented follower, but that requires that both cores are pulled out a bit to allow a cam removal. Then a core should be rotated to approximately 4:30 or 7:30 o'clock position (135 degrees either clockwise or anti-clockwise) to prevent driver entering a gaps for the cam clutch. Then a segmented follower can be used to remove the core.

Proposed edit:

For Euro Profile page:

The use of a pinning shoe is the preferred method for disassembling a double euro cylinder. STEPS?

Another method is to use a segmented follower. The c-clips retaining both cores must first be removed and then both cores can be pulled out slightly in order to remove the center cam. One core should be rotated 30-45 degrees either clockwise or counter-clockwise -- once the cam is removed. This allows the core to be removed without driver pins entering gaps for the cam clutch. At that point, a segmented follower can be used to remove the core.

Locks not intended for installation and use can be disassembled in a quick but destructive procedure. The cylinder housing itself can be cut in the middle using a hacksaw or grinder. The cam will no longer be held in place and can be removed. The resulting two cut half euro cylinders can then be disassembled as outlined above.

For individual lock page:

TBD