Lever

Lever

| This article may require cleanup to meet Lockwiki's quality standards. Please improve this article if you can. |

A lever (or lever tumbler) is a lock design that uses flat pieces of metal (also known as levers) and a bolt as locking components. In this article, 'lever lock' does not mean a locking lever handle incorporating a cylinder locking device. In most designs, the position of the levers prevents the bolt from retracting. When positioned properly, a gate in the lever allows the bolt to move (shot or withdrawn). Lever locks are historically one of the most popular lock designs, but use has declined as less expensive pin-tumbler locks have gained popularity. Lever locks are popular in Europe (specifically the UK) as residential and commercial door locks and on safes. Safe-deposit boxes in banks around the world use lever designs heavily.

History

A single locking tumbler was used on many Roman metal locks, often in association with wards. Most early door locks had no case, with a bolt and locking tumbler mounted on a backplate. From at least 13C, some locks had these components mounted in a wood stock without a backplate — this lock design is the Banbury lock (the reason for this name is unknown). These designs did not use fences and gates, but rather a simple pivoted tumbler or lever that the key had to move (typically, lift) out of the way in order for the bolt to move. Security was provided by traditional keyway warding.

Barron lock

In 1778, Robert Barron patented [BP1200] the principle of all modern mechanical security locks — the double-acting movable detainer. His patent describes 'the gating or racking to allow a stump on the tumbler to pass through the bolt, or an opening in the tumbler to allow a stump on the bolt to pass through.' These two (of several possible) realisations of the double-acting movable detainer principle are now usually described as 'lever locks'. Barron's was the first lever lock that used a fence and gates. This technique requires each lever be lifted to a precise height at which the fence can pass through the gate. Overlifting or underlifting a lever causes it to block the fence; older locks' levers only needed to be moved far enough — more than that had no effect, as long as they cleared the obstacle. Barron, and after him his son, and others, used only the arrangement of stumps on the tumblers with gates in the bolt tail. This arrangement would prove in the long run less successful than Barron's other suggestion of a stump on the bolt tail and gates in the tumblers. The double-acting movable detainer principle is still in use to this day, including pin-tumbler locks by Linus Yale, Jr.

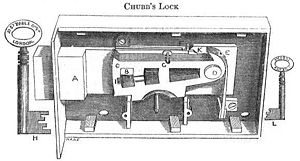

Chubb lock

In 1818, Charles and Jeremiah Chubb patented [BP4219] a lock design based on Barron's work. Their version used the placement of stump on the bolt tail and gates in the levers. This design still in use today in many locks. They also added a device called the detector, an extra lever that triggered by overlifting of the main levers. When triggered, the Detector would lock the bolt until it was reset [regulated, in Chubbs' word] with a special key. The concept of the ‘detector’ was that the lock not only responded to the true key, it also recognised a wrong key or picking attempt, and signalled this to the proper keyholder by a change of state. The concept was invented by Ruxton in 1816 [BP4027] but his realisation was not a practical success. The Chubb lock was the first to have a practical detector, combined with lever tumblers. Chubb later added false notches or serrations on the gate levers which prematurely bound components if tension was applied when the component was in the incorrect position. This anti-picking idea was originally used on Bramah locks from 1817, and also on Strutt's lever lock of 1819 — the first to use end-gated levers. It was later included in security pins many other lock designs. In 1820, Mallet patented a rotating barrel and curtain that closed off the keyhole when the key was turned and hindered independant movement of picking instuments. This addition helped to prevent decoding. De La Fons would later also be granted a patent for this same idea, in 1846. Although not widely used before 1851, the combined barrel-and-curtain are now commonly used security features of high-security lever locks.

Tucker and Reeves

In 1851, a new design surfaced with a bolt that was not rigidly fixed but could shift on one end. Patented by Tucker and Reeves, this design aimed to thwart picking attempts involving pressure on the bolt. The shifting bolt made it harder to feel the gates inside the lock as it shifted. In 1853, the design was refined to include a rotating barrel that prevented movement of the bolt until a key was inserted.

Parsons lock

In 1832, the 'balance lock' was invented [BP8350] by Thomas Parsons. This design had a plurality of symmetrical levers that pivoted around their midpoint (traditional levers were hinged at one endpoint). The key lifted the levers at one end and the bolt tail had notches at both ends. Overlifting any lever would cause it to engage the notch in the bolt and lock it at that end even if the other end had cleared the bolt. Because the balance levers take little strain, they can be thin, so that using 7 was common, and up to 20 in some safe locks.

Numerous detail variations in the lever mechanism have been invented. There have also appeared several lever cylinder locking devices, of which the Ingersoll Impregnable is notable. It has been made under licence by Sargant & Greenleaf.

Principles of Operation

A series of levers is placed in the lock. The entire set of levers must be properly raised by the key to allow a piece of metal connected to the bolt to pass through the gates of the levers, retracting or extending the bolt. Each lever may have a larger undersection or a different gate position to provide differs.

Components

- Levers

- The primary locking component of lever lock. Each lever is a flat piece of metal with a gate which must be raised to the proper position to allow the stump to pass through and retract or extend the bolt. Each lever is self-tensioned by a built in spring, sometimes referred to as the "fly". Some levers use a thinned belly section referred to as "conning" to ensure the lever interfaces with the correct bitting area on the key.

- Stump, Fence

- The stump, or fence, is a protrusion connected to the bolt. The stump prevents the bolt from being extended or retracted until the levers are properly positioned. Traditional designs have the stump and levers interconnected (gates are closed, with the stump sitting inside each lever).

- Washers

- Washers are flat metal plates placed between each lever to ensure that each lever is properly raised by each bitting cut. They are not universal, but common in outdoor facing lever locks that require a high degree of reliability, especially in harsh conditions.

- Barrel and Curtain (now combined and usually referred to simply as 'curtain')

- A curtain is a component used in the keyhole to prevent direct access to the levers after the key or pick is rotated in the lock. This protects against casual manipulation of the levers, but does not preclude lockpicking attacks completely.

Vulnerabilities

Lever locks are vulnerable to a wide variety of attacks depending on their design. Tools to pick and decode lever locks are not as widely available as their pin-tumbler counterparts, due to the fact that the tools required are more expensive and specialized to each lock than regular picks, but do exist and can be effective.

Notes

- Lever locks are not subject to key bumping or pick gun attacks.

References