Pin tumbler

Pin-tumbler

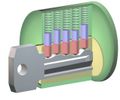

A pin-tumbler is a cylinder based lock design that uses movable pins to prevent rotation of the plug. A key is used to properly elevate pins to allow the plug to rotate and the locking bolt to be retracted.

The pin-tumbler is currently one of the most widely used lock designs in the world. Minor changes to the positions of pin-tumbler components are the basis for dimple and axial/tubular lock designs.

History

Pin-tumbler locks were originally invented in ancient Egypt. The design used a series of single pins that, when locked, would prevent movement of a bolt by resting inside the bolt itself. The key was used to raise pins out of the bolt, allowing it to retract. This was the first use of a shear line, a major discovery that is the basis for all cylinder based locks in modern use. Early pin tumbler locks, bolts, and keys were all made with wood, but eventually brass and iron were used. Many cultures adopted the design throughout history, but it would not be widely used until Linus Yale Sr. and Linus Yale, Jr. modified the pin-tumbler design in the mid 1800s.

Linus Yale Sr. improved the Egyptian design with the idea of pin pairs. In the original lock pins were required to be raised high enough to clear the bolt, but were not checked to make sure they weren't raised higher than necessary. The addition of a second pin in each chamber allowed for positive locking when components were raised too high. In this design, the key had to properly raise the pin pairs so that they could separate at the shear line, allowing the locking bolt to be retracted. Yale Sr. also added springs above the pin pairs to force them down to their locked position when no key is inserted.

Linus Yale Jr. continued his father's work by improving the design of the pin-tumbler. He made it smaller, more reliable, and changed the design of the key to be flat instead of fluted. This type of key is still used by modern pin-tumbler locks.

The design of the pin-tumbler lock has remained virtually unchanged since the Yale familys' contributions. Master keying allows the addition of pins in each chamber to provide various methods of keying a particular lock or group of locks. Other improvements have been in the form of auxilliary security mechanisms to prevent compromise. Security pins, sidebars, and side pins were created to frustrated lockpicking. Other anti-picking modifications exist, such as rotation or telescoping. Finally, ball bearings and hardened steel rods or discs are now inserted into the plug or cylinder to protect the pin stacks against destructive entry.

Principles of Operation

Pin tumblers are a series of pin stacks pushed down by a spring. Each stack must be properly raised to allow pins to separate at the shear-line. Once all pin stacks are separated the plug can freely rotate and actuate the locking bolt to lock or unlock the lock.

An incorrect key will not align all components correctly; rotation of the plug will be blocked at the shear-line.

A pin-tumbler cylinder, correct key inserted and plug rotated.

Vulnerabilities

Pin-tumblers are vulnerable to a wide variety of attacks. The specifics of the pin-tumbler design and manufacturing tolerances will determine the exact vulnerabilities present, but most pin-tumblers are vulnerable to at least one or more of the following:

- Lockpicking

- Pick Guns

- Key Bumping

- Tryout Keys

- Comb Picks

- Impressioning

- Decoding

- Bypass

- Desctructive Entry